innovation for fighting mastitis

Disinfection of clusters

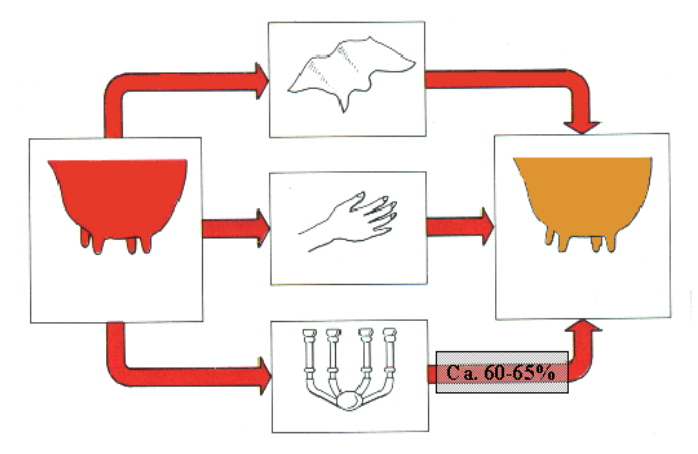

Washing clusters between milkings is a hygiene procedure that aims to minimize the risk of infections and improve the quality of the milk obtained. Increasing awareness of milking hygiene and limiting the use of antibiotics for inflammations that have occurred means that more and more farmers decide to implement this procedure.

Milking point hygiene is the most important tool in the fight against mastitis in cows. It is not only necessary, but is a standard of modern breeding. To avoid cross-infection and the transfer of diseases from cow to cow, post-milking hygiene should be supplemented with inter-milking disinfection, as well as disinfection of staff hands and footwear. The most effective disinfection methods should be introduced and implemented into the daily routine during milking.

In order to limit the decrease in profitability of breeding farms, it is necessary not only to limit the presence of somatic cells in milk, but also to limit the amount of antibiotics used. New regulations regarding the amount of drugs administered force breeders to search for new technologies that will limit the problems of infections in their herds.

Estimates suggest that a dirty milking machine can infect between 6 and 8 cows during a single milking. An additional 10% of infections are due to poor hand hygiene by milkers.

Mastitis prevention

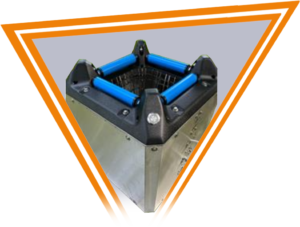

Hyperin CluStar is an automatic washer designed for washing clusters. It allows for washing the units immediately after each milked cow. This solution effectively limits the spread of mastitis among dairy cattle by keeping the milking units permanently clean. This has a direct effect on a strong reduction in cross-infections.

The device is made of acid-resistant stainless steel. The washing process takes place in a 3-5 sec cycle, using alternating sprays of water and disinfectant. The spray is carried out using fixed nozzles and nozzles placed in a specially designed rotating basket.

During one cycle, the milking cluster is simultaneously washed and disinfected both from the outside and inside. An additional advantage is the constant disinfection of the milkers’ hands and shoes.

Using the Hyperin CluStar automatic machine for washing between milkings prevents the formation of environments (biofilm) in which bacteria can multiply quickly and effectively.

The parameters of the machine are controlled using an application, thanks to which it is possible to adjust the washing parameters to the systematics of a given farm.

A technical solution that allows for easy integration into the established daily milking routine.

The set moves around the milking parlor using a trolley on a suspended, suitably adapted strip. This allows the unit to move along the parlor with the milker and allows for convenient use of the system.

Using the Hyperin CluStar machine for washing between milkings prevents the persistence of environments in which bacteria are able to multiply quickly and effectively.

Innovative washing machine that has already obtained a patent for innovative design features in Poland and the United States. Additionally, it is waiting for approval of patents in New Zealand, Australia, Canada and, of course, in the European Union.

An automatic device for effective cleaning and disinfection of clusters

Performance and functionality:

• Cleans and disinfects the milking cluster in every cycle.

• Fast cleaning cycle: 3-5 seconds, ensuring a quick changeover between milkings.

• Reduces the risk of Thermoduric bacteria and cross-contamination.

• Prevents the build-up of biofilm.

• Uses clean water in every cycle, ensuring thorough disinfection.

• Disinfects the operator’s hands and footwear, contributing to overall hygiene.

Water and chemical consumption:

Allows dirty water to drain onto the floor during the cleaning cycle, preventing contamination of the cleaning system.

Uses approximately 1 liter of water per full cycle.

System design and compliance:

Powered by a 24 V system.

The device is fully programmable, offering adaptation to different cleaning cycles.

It can be installed in different configurations: fixed (rotary), on rollers or in a gantry system (herringbone).

Equipped with pressure regulators to control the flow of water and detergent.

Design and compliance:

Made of stainless steel (S/S) and acid-resistant plastics for durability and corrosion resistance.

Weight: 30 kg.

Dimensions: 520 x 520 x 620 mm.

Patent for innovative design features.

Pending CE approval and complies with the EMC Directive (2014/30/EU) in the European Union.